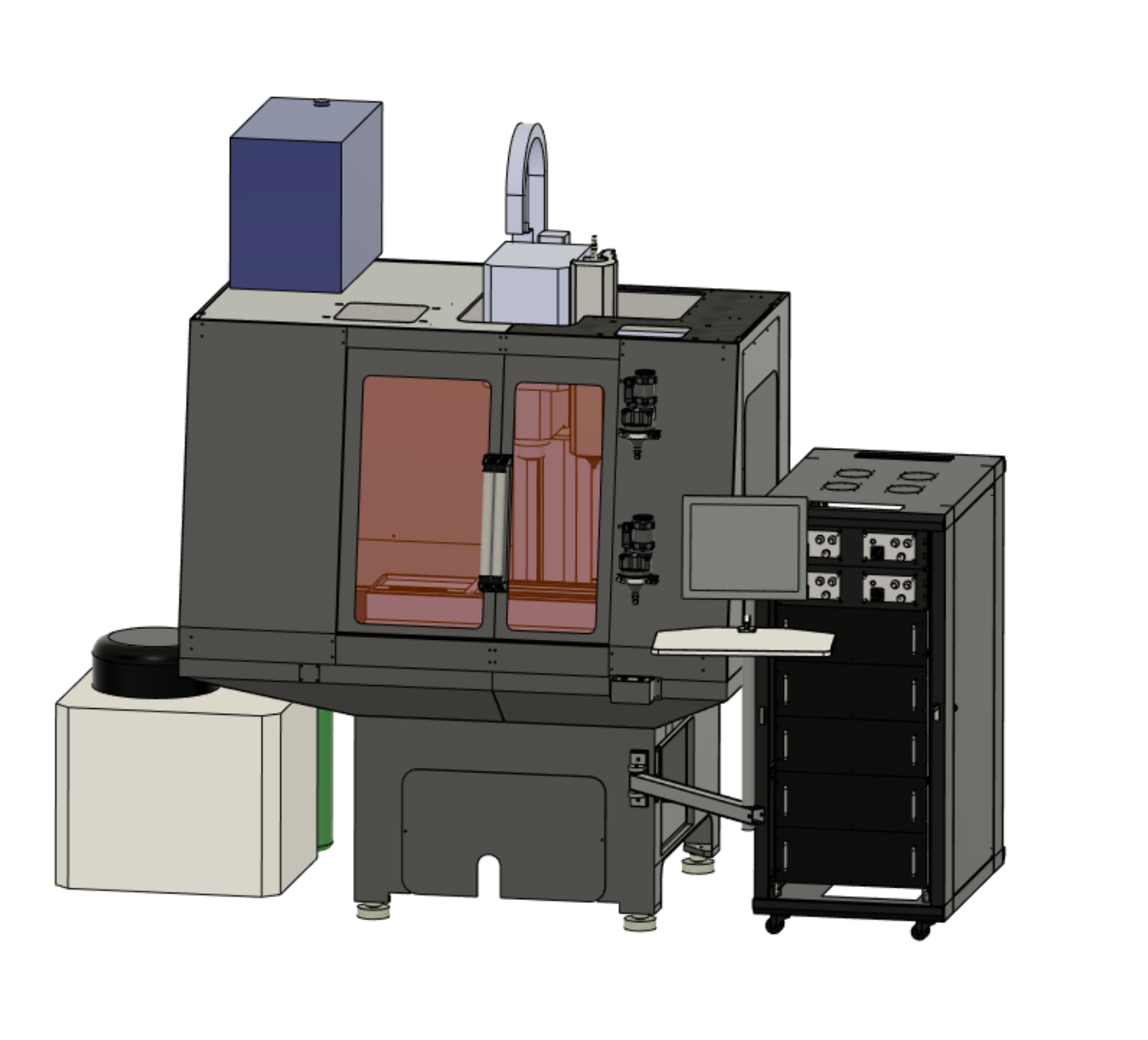

The AM1

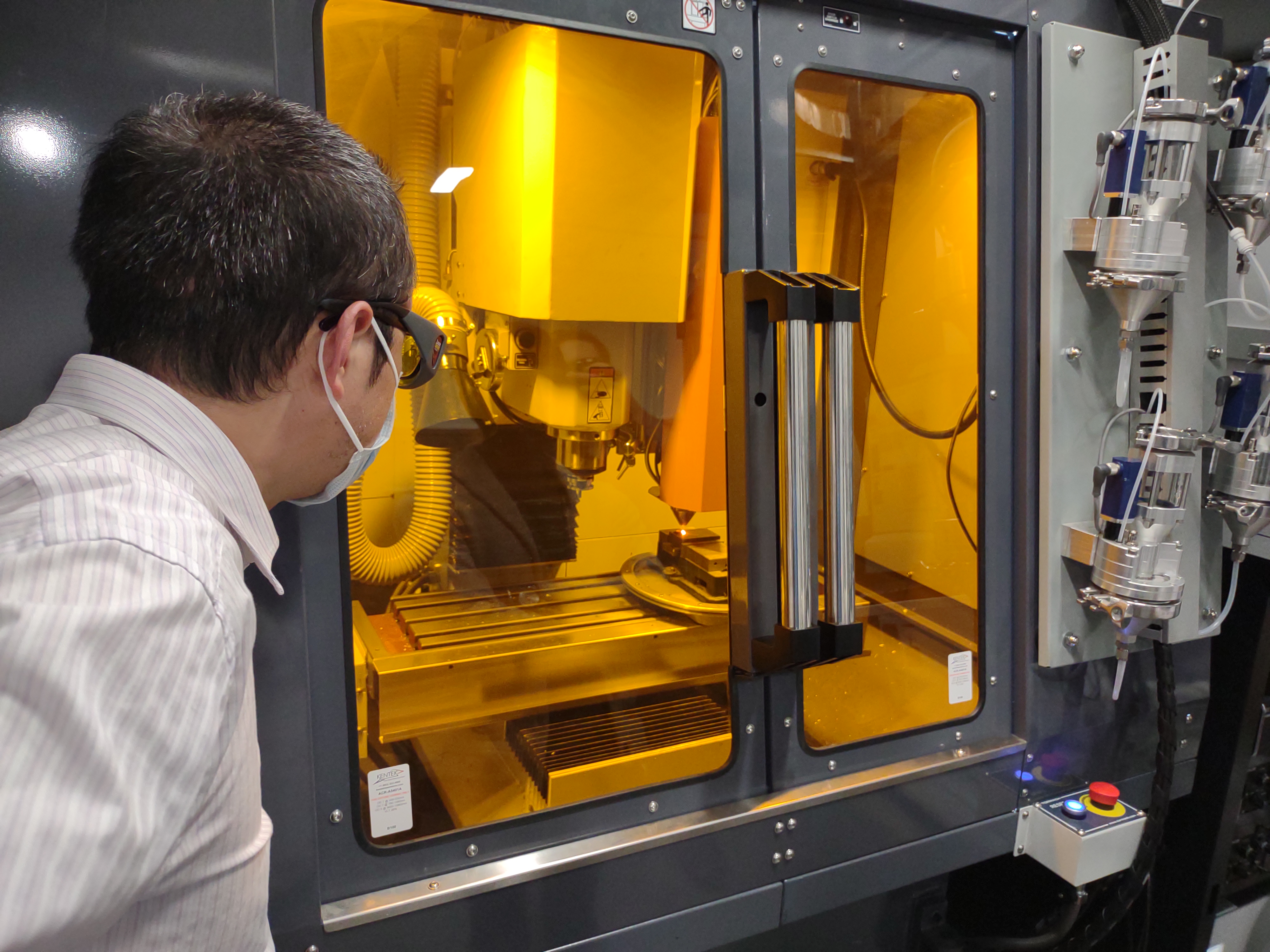

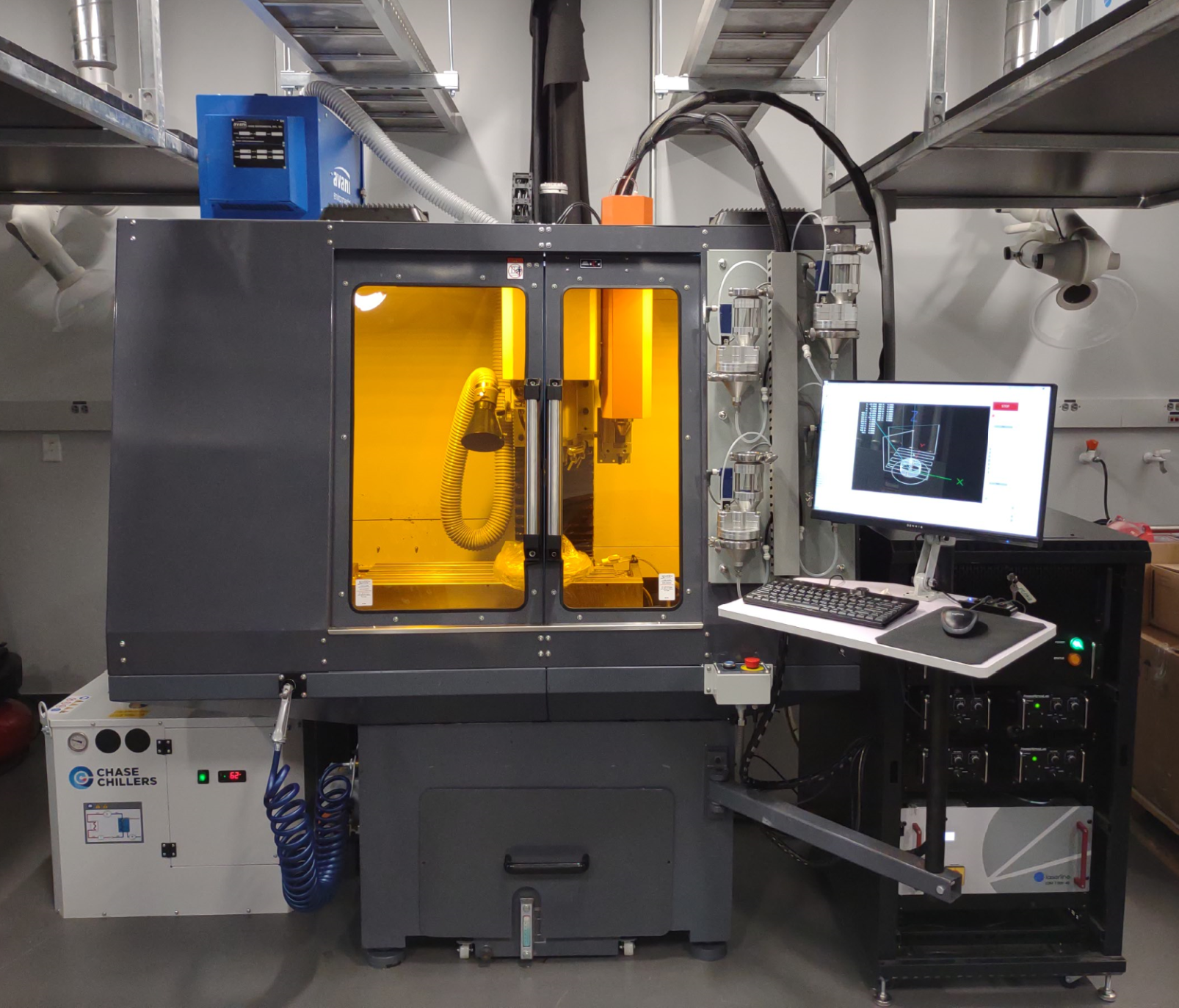

The ProtoQ AM1 is a small-format hybrid manufacturing system which combines blown-powder directed energy deposition with CNC machining in a unified and cohesive system. The AM1 is highly adapted for the needs of materials research, component repair, tool and die modification, and more.

- Fully hybrid manufacturing: additive and subtractive

- Materials: titanium, steel, inconel, stainless, copper*, and aluminum*, and others

- 2 hp 10,000 RPM BT30 spindle

- 4 high-precision powder feeders (more upon request)

- Programmable with industry-standard G-Code commands

*with AM1b (blue laser variant)